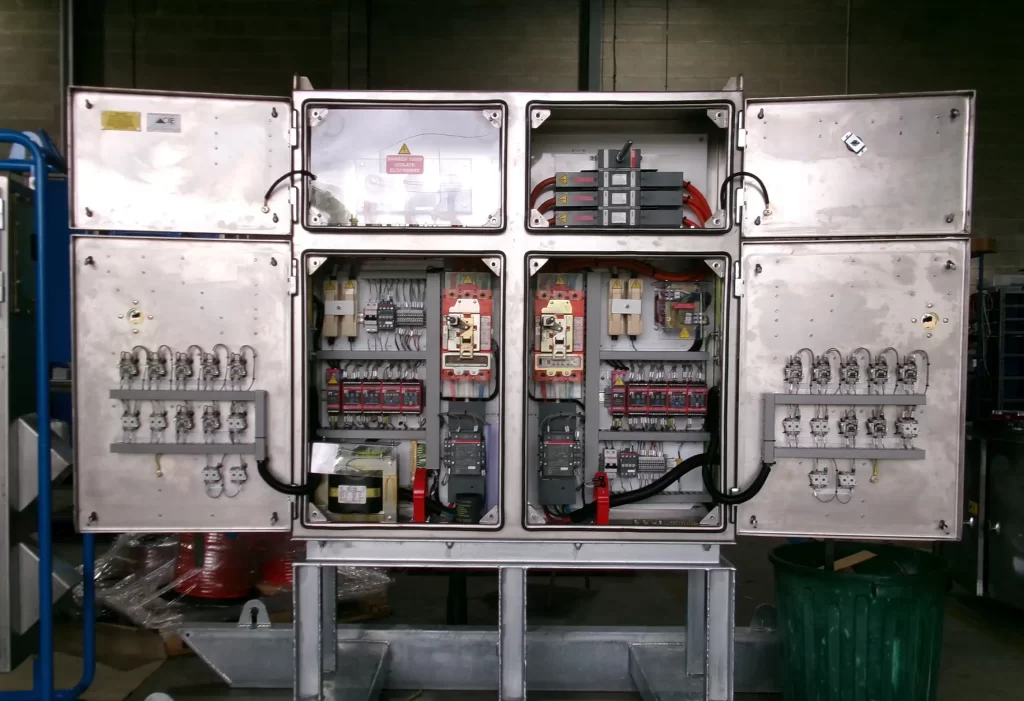

Established in 1996, CIE Pty Ltd is an industrial electrical mining switchboard manufacturing company with a core capability of high-quality products and services.

C.I.E. (Cristaudo’s Industrial Electrics) Pty Ltd ATF CIE TRUST

C.I.E. (Cristaudo’s Industrial Electrics)

Pty Ltd ATF CIE TRUST